Machinery

Discover our Range of Lapidary Machines Made in Australia for Superior Quality and Craftsmanship

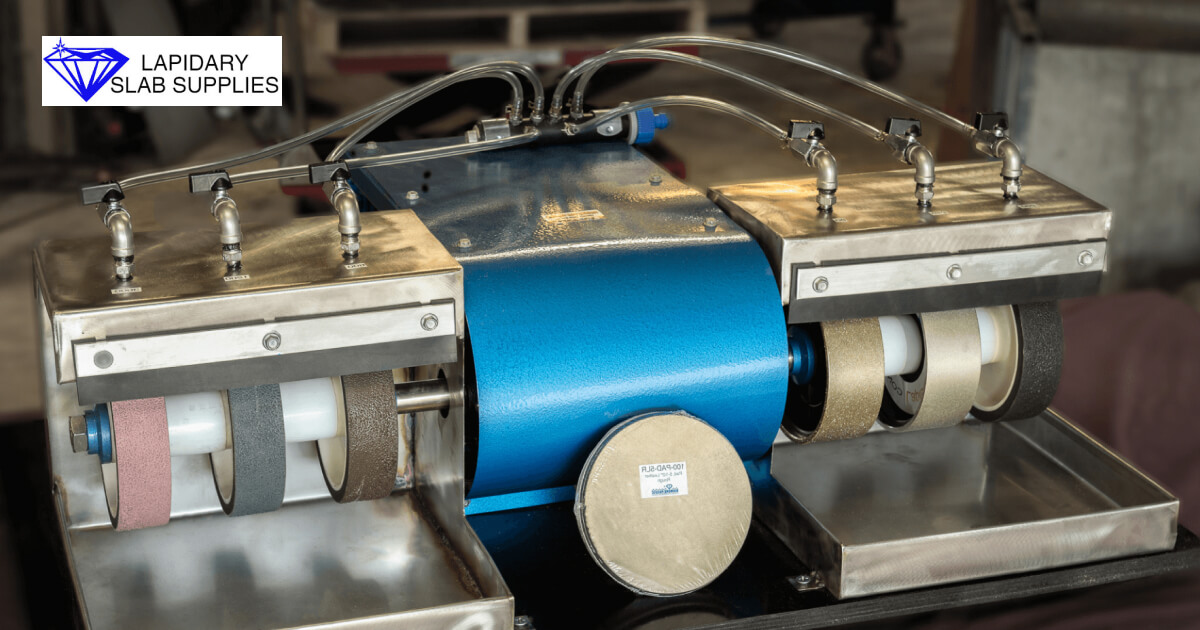

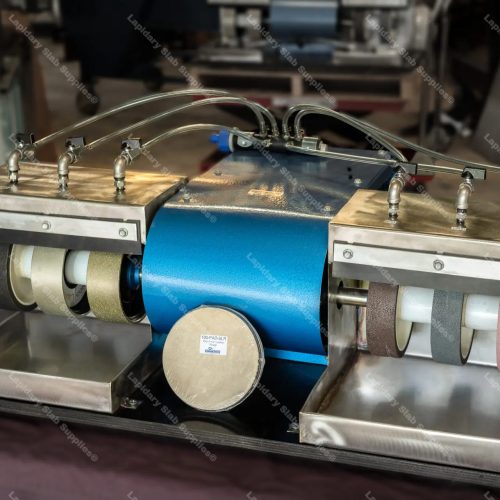

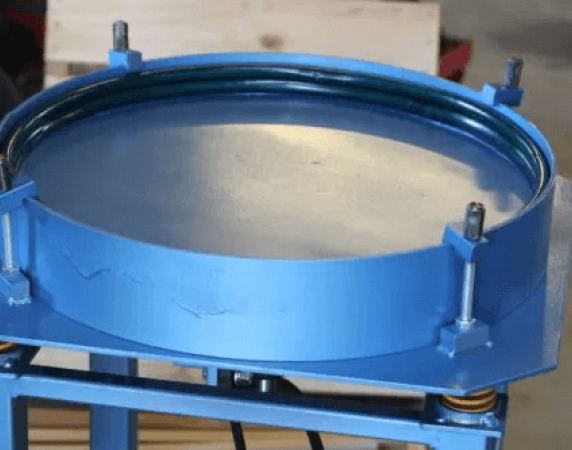

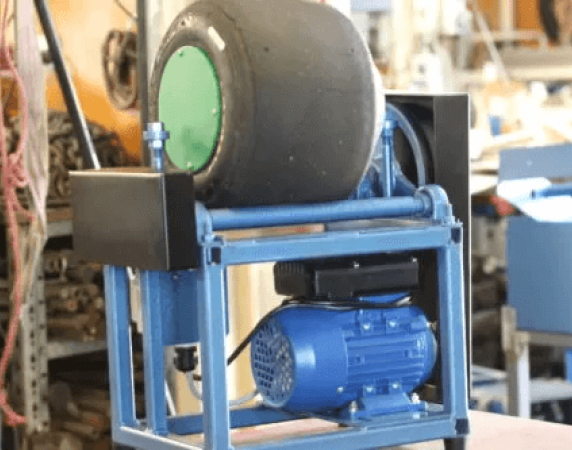

Offering all types of custom-built lapidary machinery (including Flat Laps, Trim Saws, Grinding machines, tumblers, and large Power-fed Saws).

We specialise in quality products and we take great pride in our self-design and hand-crafted machinery.

All of our machines being freighted around the country are bubble and plastic wrapped before then being custom created in pine timber (to the size of the machine) and on a custom-made pallet so they are well protected during transit to you and for easy forklift removal at the other end!

Discover the Art of Lapidary with our High-Quality Custom-Built Lapidary Machines

Lapidary machines are specialised and essential equipment used in the lapidary field, which involves the cutting, shaping, grinding, and polishing gemstones, rocks, and minerals to create stunning jewellery, decorative pieces, and artistic displays. These machines are used by lapidary enthusiasts, hobbyists, and professionals alike to transform rough materials into beautiful, polished gems and stones. Whether you’re a seasoned lapidary artist or just starting, having a suitable lapidary machine can significantly enhance your ability to create high-quality pieces.

Cutting is the first step in the lapidary process. Lapidary machines such as lapidary diamond saw, Lapidary trim and slab saws and lapidary rock cutting saw precisely and efficiently cut rough materials into smaller, more manageable pieces. These machines are equipped with diamond-coated blades that can easily cut through various types of rocks and minerals, allowing lapidary artists to obtain the desired shapes and sizes for their projects.

Shaping and grinding are critical steps in lapidary work, and lapidary machines such as Lapidary cabbing machines and flat laps are used for these purposes. Lapidary Cabbing machines, also known as cabochon machines, are designed to shape and polish cabochons, rounded, domed gemstones used in jewellery making. They feature grinding and polishing wheels that can shape and polish rough materials into smooth, round cabochons of various sizes and shapes. On the other hand, flat laps are used for grinding and polishing the flat surfaces of gemstones, rocks, and minerals. They consist of rotating disks with abrasive surfaces that can remove rough spots and shape edges and achieve smooth, polished surfaces on the lapidary materials.

Polishing is the final step in the lapidary process, and lapidary machines such as grinding and polishing machines, tumblers, lapidary rock grinder polishers, stone polishing machines, lapidary grinder polishers, and lapidary rock mineral grinding polishing machines are used for this purpose. Tumblers are essentially barrels that rotate and tumble rough materials with abrasive media, water, and polishing compounds to achieve a smooth, polished surface. They are commonly used for tumbling small stones, beads, and cabochons, providing a consistent and polished finish to lapidary pieces. Lapidary grinder polishers are specialised machines used in the lapidary field for grinding and polishing gemstones, rocks, and minerals. They are designed to shape and refine rough materials into smooth and polished surfaces, enhancing their beauty and value.

When choosing lapidary machines, there are several factors to consider. Motor power and RPM are essential for determining the cutting and grinding power of the machine. The size and capacity of the machine, including the work surface or cutting blade size, should be suitable for the type of lapidary materials you work with. The material construction of the machine should be durable to withstand the demands of lapidary work, and ease of use is crucial, especially for beginners or hobbyists.

Regular maintenance is essential to ensure lapidary machines optimal performance and longevity. This may include cleaning the machine after each use, checking and tightening bolts and screws, replacing worn-out parts or consumables, and keeping the machine well-lubricated and cooled, if applicable.

Lapidary machines and lapidary accessories can be purchased from specialised equipment stores, online equipment retailers, and lapidary trade shows like Lapidary Slabs Supplies. It’s essential to choose reputable sources to ensure the quality and reliability of the lapidary machines and accessories.

Investing in high-quality, Australian-made lapidary machines can provide the precision, durability, and performance needed for your lapidary projects. With the suitable lapidary machine, you can unleash your creativity and transform rough materials into stunning gems and stones that can be cherished forever.

Types of Lapidary Machines we offer:

Our Brands

High-Quality Australian Manufactured Lapidary Machines

Rating on Facebook 5.0 (15 Reviews)

With our comprehensive inventory and commitment to quality, we strive to be your go-to lapidary supplier, providing you with the lapidary tools and supplies you need to unlock your creativity and achieve stunning results. Discover the convenience and reliability of our online store, or visit our physical location to experience the exceptional service that sets us apart as a trusted Lapidary supplier.